Dropping a wireless signal or sending a document to print that never quite makes it is frustrating, but with so many users trying to access wi-fi networks at the same time, even the strongest wireless network is susceptible to signal loss.

Commenco receives calls almost every day from companies desperate to get rid of their wireless “dead zones.” We thought it might help if we shared some of the most common reasons why they’re experiencing problems.

1. Material Menaces

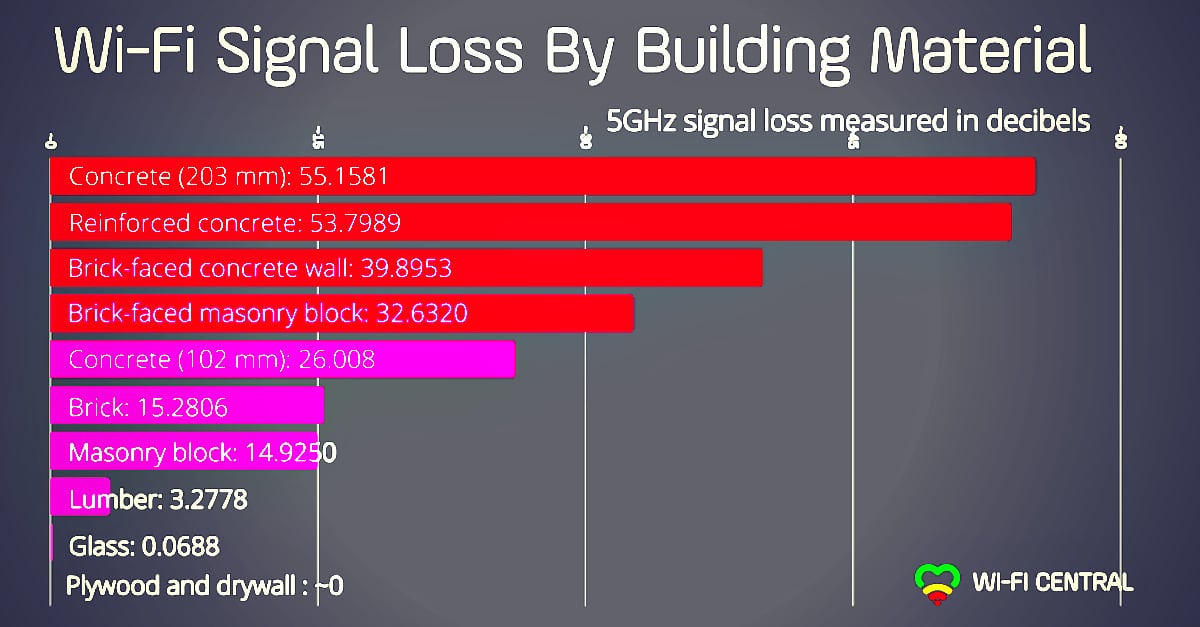

“Construction materials don’t always play well with wireless signals,” says Ralph Aguilar, Commenco’s Director of Commercial Services. A lot of commercial buildings are made of concrete, and many of them have metal ductwork or HVAC systems that interfere with wi-fi.

“We just have to figure out how to design around all the obstacles to get coverage where it needs to go. And usually, we still need to come back out and make adjustments because businesses are always growing and changing”

It’s no secret concrete walls are a problem for radios and wi-fi signals, but Aguilar says the concrete itself isn’t the problem. “It’s the rebar inside that blocks the signal. There’s a lot of steel running through concrete and steel absorbs signals.”

Although it may take some creativity, concrete structures built with a lot of rebar or steel can still be wired to eliminate dead zones.

Even the bright electric buzz of fluorescent lights can make trouble for wireless signals. Aguilar says that’s why every building looking for great wireless coverage needs to have their property assessed. “You have to take environmental materials, existing conditions, and other factors into account when you’re designing a wireless system, and not all buildings are the same.”

Offices, warehouses, and distribution centers can seem like a piece of cake after some of the projects Commenco’s team has conquered.

“Imagine installing a two-way radio system in a grain elevator that goes 700 feet into the ground,” says Aguilar. “It took a lot of work, but we figured out how to make it happen despite a thick concrete tunnel, a grain conveyor belt and powerful electric motors. That’s probably the most difficult environment I’ve ever encountered.”

Motors and other machinery that produce or consume large amounts of electricity are another common reason people experience dead zones. Electrical equipment can cause chaos for nearby wireless signals.

Did you know windows can be a problem too? Aguilar says specialized glass that filters ultraviolet sunlight can have metallic coatings and multiple panes that repel wireless frequencies.

“You intuitively think a facility with a lot of glass will work better because signals should pass right through something you can see through. But these newer types of commercial glass are made with safety in mind so they do much more than provide a view ”

2. Operator Errors

“There are perceived dead spots and then there are legitimate dead spots,” Aguilar points out. “Perceived dead spots are when a system doesn’t seem to be working right but the problem is how it’s being used or what it’s being asked to do.”

Misunderstandings can stem from unrealistic expectations when a clearly defined scope of coverage in the planning stage is overlooked or forgotten. Untrained or new employees can also get the wrong idea about how the equipment works. Aguilar says a perceived dead spot can sometimes be traced all the way down to a specific user.

“I remember trying to get to the bottom of a two-way radio problem tied to a particular stretch of time every day in a particular area of a company. It took a while, but we finally determined the problem was one person with an unusually soft voice. Co-workers couldn’t hear this person because they were basically whispering into their radio. Once they started speaking up a little bit… no more dead spot.”

Aguilar says Commenco also gets calls from businesses who tried to save money by having an employee or a friend install their company’s wireless system.

“They eventually end up calling us because they may have accidentally created negative network feedback issues or new dead spots in the building.”

Businesses can also end up with a big fine from the Federal Communications Commission if they don’t stay on top of their licensed radio frequencies. And don’t forget about the Fire Marshal inspecting buildings to make sure their Emergency Responder Radio Coverage is up to code.

3. Planning Pays Off

If you work in a large building, or multiple buildings on a property, you may be able to save some money by focusing on areas where coverage matters most and skipping areas where coverage isn’t a big priority. Paying for blanket coverage so you can get a great signal in the storage room or other low traffic zone may not be worth it.

“Companies willing to invest a little time upfront figuring out where their priority coverage zones are can save themselves a lot of hassle down the road,” says Aguilar. “Many times we troubleshoot a ‘dead spot’ and find the network is working just fine. It may be employees are moving in and out of the coverage range so they can’t always connect to the system .”

Expanding a network coverage area can be tricky, but we have so many great technology tools that help us solve these kinds of problems now so companies really shouldn’t have to struggle with dead zones anymore. We can strategically place antennas, wi-fi access points, and network boosters in certain areas and completely change the game for a business.

Our team works closely with companies to design scalable wireless infrastructure plans, and we also train them on the ins and outs of using and maintaining new wireless equipment. There aren’t too many things businesses rely on as much as they rely on wi-fi and our team is proud to play a small part in helping them get the most from their technology investments. #ToolsNotToys

Tired of losing your wireless signal? Maybe it’s time for a BOOST >>