It’s the wild west in fulfillment and distribution these days as the coronavirus orders up e-commerce demand like never seen before. As we’ve discussed, pandemic pressures heavily favor well-prepared distribution centers in Kansas City that made a priority of adopting modern technology early while other operations delayed and are now scrambling to catch up.

Moving products faster is everything if you want to remain competitive in the biggest e-commerce crunch of our time. A complete tech solution that combines the right software and hardware for your operation’s specific purposes and processes is the key to staying in the game.

“Technology is really the only option for enhancing efficiency and speeding things up,” says Mike Markham, Commenco’s Director of Technology Solutions. “A complete solution moves your whole operation forward to meet modern challenges, and right now those challenges are suddenly hitting home.”

Markham’s extensive experience in both hardware and software makes him an especially valuable source of guidance when distribution centers seek a level-leap to keep their businesses competitive. The phones at Commenco keep ringing despite the economy’s slowdown and Markham is busy connecting new customers with Commenco software partners based on their needs and then following up with hardware to complete plans.

“Whether you’ve been disciplined about adopting technology all along or are just now trying to catch up, you’ve got options,” explains Markham. “It’s hard to tell if this e-commerce surge will ever ease, so you should give serious thought to making a change asap. The future of your company could depend on it.”

Software as a Starting Point

While distribution centers full of forklifts and pallets of bulk products are still out there and have a place in the industry, the dramatic shift toward e-commerce has re-shaped scores of other centers around working faster with more precision at an increasingly granular level. As the backbone of an operation, Warehouse Management Systems (WMS) are being pushed harder and harder to find better ways of optimizing time and resources.

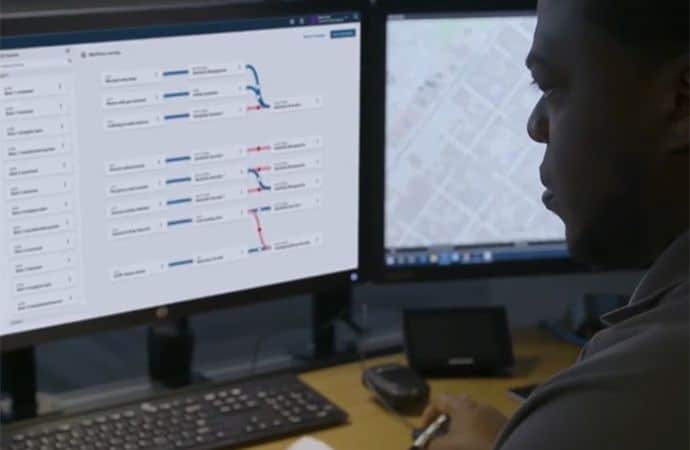

Software is no longer simply common ground for data inputs, it now analyzes and understands a distribution operation, hunting down even the smallest areas for improvement or opportunity. WMS software hard at work at the most advanced distribution operations in Kansas City already seems to be pushing efficiency near perfection. Markham says it’s really something to see.

“Products are being picked from storage, packaged and prepared for shipment right there in the aisle on the spot. In essence, it’s picking, packaging, and shipping at the same time. That’s the level of efficiency it takes to compete now.”

Efficiency also involves a tight communication connection both inside and outside a distribution center. Markham says WMS software must be able to keep everyone along the chain in the loop. “Systems now communicate better within a distribution center and externally with shipping companies, manufacturers, and consumers. Apps talk to all kinds of other apps in real-time conversations that shrink timelines and inform smarter decision-making.”

Hardware that Works the Way Workers Do

WMS software can only deliver on its potential if it’s matched with the right hardware to pull in all the right data. While traditional methods still make sense in certain environments, the increasing pace of e-commerce is forcing hardware to evolve to further streamline processes.

“When you’ve got workers picking through boxes for small products, wearable technology becomes more valuable,” says Markham. “Barcode scanners tied to your finger or wrist, or things like smart glasses free up your hands for other work that moves things along faster.”

Other tools such as Radio Frequency Identification (RFID) can go even farther by largely automating inventory tracking in a distribution center. Two-way radios packed with specialized software bring teams closer together, allowing them to coordinate smarter decisions and movements throughout distribution centers in real-time without interruption. Access control systems lockdown security risks and analyze the flow of activity through a facility. And did you think surveillance cameras are only for security?

“Cameras are being integrated into business operations more and more,” explains Markham. “They’re now smart enough to confirm key movements and verify compliance. They can think, analyze, and understand to do things like validate shipments and ensure operations are going smoothly with every worker sticking to assigned areas of a facility.”

Put it all together and you get the picture of the ‘complete solution’ you hear Markham and other Commenco managers talk so much about. The tight integration of both software and hardware is the only way to punch your ticket to compete in the distribution big leagues Kansas City has joined. And there’s no better time than now to make it happen. Who knows how far the pandemic will push e-commerce tomorrow, the next day or the next year?