Kansas City’s rise to prominence in the logistics arena is getting a push from growing demand for cold storage and refrigerated warehouse space. And while food manufacturers, grocery stores, and freight-based businesses search for solutions, third-party logistics companies with a sharp focus on technology are in the best position to win.

A Warm Welcome in KC

Food on-demand culture, driven by changing lifestyles and pandemic restrictions, is making waves up and down cold supply chains. Commercial real estate experts say as much as 100 million square feet of freezer and cooler space will be needed to handle the developing surge, and Kansas City businesses are ramping up to meet demand as key players on the global cold storage stage.

Nearly all food produced or imported in the U.S. passes through a distribution center before it reaches consumer dinner tables. Much of it flows right through the heart of America and that’s one reason Kansas City is under a global spotlight. As KC Smartport points out, we’re right in the middle of the country’s agricultural region, which shrinks delivery times and makes a lot of customers happy.

Temperature-controlled storage involves many additional compliance requirements so most organizations outsource the responsibility to distribution and warehousing centers that have the flexibility and resources to meet unique demands. Third-party powerhouses like Northpoint Logistics and others in the Kansas City area have a big head start with their commitment to cold specialization backed by an array of supporting technologies.

A Chilling Challenge

Cold or refrigerated storage translates to just about anything that needs controlled temperatures to prevent decay or regulatory trouble. Requirements are extremely rigid and can vary widely. The nature of the products themselves can be incredibly diverse, ranging from natural ingredients and food to flowers, medications and even furniture and artwork. And every cold chain customer can be different with specific needs tied to shelf life, temperatures and transportation time limits based on spoilage risks.

Cold storage isn’t something easily tacked onto an existing operation. A distribution or warehousing center must be ready to reshape itself around temperature-controlled environments. Dedicated areas are needed to manage products and materials. Storage can take a variety of forms, from relatively small containers to entire cold rooms or even blast freezers with the capacity to quickly cool.

A poorly planned operation will watch profits go out the window from excessive energy use. Cutting corners on things like insulation and door quality can quickly backfire and end up costing more than you saved. And moving inventory around the facility and onto delivery trucks must be carefully planned to limit exposure to ambient temperatures.

Fine-tuning operational processes is the best way to unlock opportunities, and ultimately, the technology you use can help or hurt your efforts to compete.

Smart Tech Can Crack the Cold Code

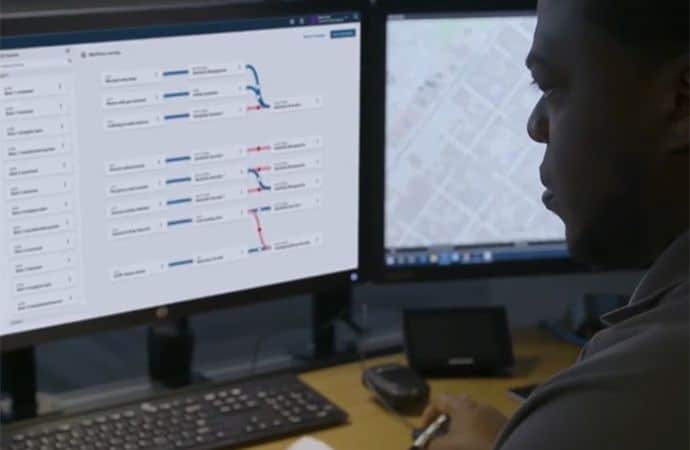

At the heart of distribution and fulfillment operations is a good Warehouse Management System (WMS). Throw in freezing temperatures and the demands of the WMS become more complex. Cold storage WMS has to be sophisticated enough to monitor timing and temperature, alert you to problems before they become serious, and continuously share information with the rest of your supply chain.

RFID Is Up For The Job

Cold storage is a great environment for Radio-frequency Identification (RFID). RFID devices can connect directly to your WMS to eliminate delays in inventory communication. The technology ensures data flows seamlessly in real-time, which can help you make more informed decisions along the way.

Distribution and warehouse centers specializing in cold storage also depend on specialized industrial labels. Products that stay in the deep freeze or pass through a variety of temperature-controlled environments require custom adhesives and specialized paper. Shelving, racks and even directional labels on walls and freezer doors that aren’t equipped with the right labels won’t hold up to the job and the increase in operational disruptions that causes isn’t worth the risk.

Tech That Stands The Test of Time

Industrial two-way radios may not be new but there’s nothing faster than voice communications and every second counts in a cold storage facility. Even if they’re spread out over a large facility, team members using two-way radios are only a button push away from reaching another person. The right two-ways for cold storage facilities must have batteries designed to withstand brutal cold, sudden fluctuations in temperature, and harsh day-to-day use.

In a cold storage situation, radios can reduce the time needed to pass in and out of storage areas and the corresponding energy waste of doors opening and closing unnecessarily. The devices can also literally be a life-saver in a crisis if a worker needs emergency help in frigid temperatures where cell phones stop working.

The Right Tech Partner Helps You Compete to Win

We understand speed and accuracy are critical for success in your industry and our team has the equipment and expertise to help you optimize your cold storage operations and increase your competitive advantage.

See all Commenco’s equipment and service offerings for warehousing >>