Key Points:

- Providing additional warehouse services is a valuable opportunity

- Advanced software positions you to do more while keeping prices competitive

- A strategic selection of hardware tools expands performance

Storage, shipping, and receiving are fundamental drivers of a warehouse business, but there’s even more potential in providing extras for bigger supply chain customers. Here’s a look at essential tools to help you qualify and compete for additional opportunities.

The Rewards of Doing More.

Warehouses equipped to go the extra mile in managing and preparing inventory are better positioned to grow their business. Producing endcap displays and bundling product varieties into single, shippable SKUs are just two examples of capabilities that make an operation stand out on the competitive landscape. Raising your profile is about doing more for customers and doing it fast, and the rewards are well worth it.

“Performing service at the warehouse so that manufacturers and distributors don’t have to do it at their own facilities can really strengthen relationships and help your bottom line,” says Mike Markham, Commenco’s Director of Commercial & Industrial Technologies. “A greater capacity to handle product and rework it quickly when conditions change creates possibilities many warehouses want.”

As supply chains stretch, warehouse operations must be more nimble and resourceful to help iron out kinks. Demand for specific inventory can fluctuate wildly and sorting requirements can shift from day to day, turning productivity into a Rubik’s Cube. The ability to roll with the punches invites new revenue potential, but requires a firm break with old methods.

“You can’t do it on a piece of paper,” says Markham, after years of coaching traditional warehouses into the digital age. “You need good technology tools that forge smarter, streamlined processes.”

Invest In Software As Ambitious As You Are.

What are the limits of your Warehouse Management System (WMS)? The decision to migrate from clipboards and printed spreadsheets to a WMS is a big step in the right direction, but don’t be short-sighted. Make sure your WMS is capable of growing with your portfolio of services. Markham says you want a system sophisticated enough to put you in the running for additional business.

“A good WMS allows you to check boxes on a Request for Proposal (RFP) that qualify your operation for more kinds of work. You’ll need it to handle everything from barcoding complexities to rigid compliant labeling specifications. In most cases, there’s just no other way to efficiently crunch all the data involved.”

A powerful WMS not only strengthens your capacity to take on more work, it also creates efficiencies to keep your rates competitive. “Bigger customers know what they’re willing to pay, and if they can’t get it from your warehouse they’ll move on to someone else.”

The earlier you deploy a robust WMS, the better. Depending on your specific operation, a more fundamental WMS may get you by for a while. But if you’re aggressively going after new business, you don’t want to find out the hard way that you need a more capable system. Landing a lucrative customer that requires a sudden switch to smarter WMS can be painful. Ditching your old system, deploying a new one, and retraining your staff while onboarding of a new customer at the same time is something you want to avoid if possible.

Deploy High-Quality Mobile Tech Tools.

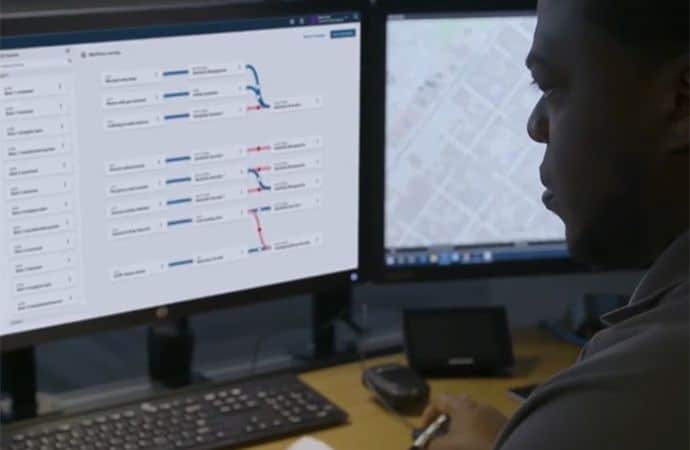

Doing more, working faster, and keeping your rates competitive has a lot to do with the mobile devices your employees use to manage inventory and feed data into your WMS. Selecting the right mobile computers reduces unnecessary movement throughout your warehouse, speeds up productivity, and empowers your staff to flex for special project work.

Set aside time to closely examine every step of your operation with a technology consultant. They can help you choose mobile devices in forms that precisely match specific work and working conditions, ranging from traditional handhelds to hands-free wearables. And stick with durable hardware that won’t disappoint.

“You don’t have to break the bank to get well-made devices, but you have to choose brands and designs that you know will hold up under the stress of relentless use,” says Markham. “Many options on the market look right, but should definitely be avoided. A trained eye can pick up on telling signs of poor quality. The price may be very low but the device won’t last a year or even a few months. And then you wind up spending more on replacements than you would have spent by just investing in a quality device upfront.”

Higher quality mobile scanning devices will also enable more technology functions to help streamline processes and make them more flexible for custom projects. The integration of shipping software and other extended capabilities will also be possible, allowing more work to be performed from each device, and cutting the time and hassle of switching between systems. Plus, better devices will perform more reliably when loaded up with demanding software.

Choose Printers and Labeling That Stick To High-Value Work.

As warehouse outputs become more precise and customized, sophisticated industrial printers are a rising priority. Customers increasingly want to combine inventory and produce printed data in a variety of ways. Custom orders can vary from small and temporary to large and long-term, with routine modifications in labeling information, and no room for error.

“Your printers must be smart enough to understand and effectively translate a wide range of data to labels,” says Markham. “And they must be durable enough to hold up under changing demands. Complicated projects can get very difficult if you’re troubleshooting labeling errors or regularly taking printers offline for repair. You can’t afford the delays.”

The labels themselves are just as important. Bigger manufacturers and distributors, especially in the e-commerce space, frequently need labeling changes. Endcap and kitting specifications shift, recalls trigger relabeling, regulatory compliance requires special label materials, the list goes on. Markham says labeling is far more complicated than you might think and deserves serious attention if you want to expand your services.

“Labeling flexibility can be critical. There are so many facets, from label size and shape to data load and multiple layers made of varying materials. Sometimes labels will contain different sets of information that different systems will need to read after they leave your warehouse. And your printer must be able to handle everything without fail. Printing must be flawless and the labels themselves need to match the purpose and circumstances of each project perfectly.”

Plan For Your Potential Now.

Robust software systems connected to high-quality hardware tools are inside every warehouse prepared to deliver the extra services manufacturers and distributors are eager to offload. Facility managers focused on removing limits and expanding capabilities know the right technology is what it takes to qualify for additional work from customers in a market that’s getting more demanding.

If you see the potential of your warehouse hinging on the granular management of inventory more than the simple movement of pallets, now is the time to upgrade. A smart selection of tools frees your business to soar to the next level, and prevents your competitors from passing you by.