When speed and efficiency are top priorities, the search for smarter ways of working extends to every corner of your business. These two solutions can immediately make a difference.

1. Mobile Workstations

A customer suddenly needs new regulatory labels printed and slapped on thousands of boxes before they ship, or maybe a big chunk of inventory needs to be pulled out and sorted all over again. Special project work routinely pops up in busy industrial facilities, and usually, the most efficient approach to tackling it is to build a new workflow around the location of the materials involved in the project.

“You want to limit how much running around your people must do to get the job done,” explains Mike Markham, Commenco’s Director of Technology Solutions. “The more time workers spend crisscrossing the floor gathering tools and doing things like retrieving fresh batteries, the longer the project takes to complete.”

Markham says employees tasked with special projects will often find a way to string together their own mobile solutions, despite the safety risks.

“I’ve seen carts rigged with devices wired to a car battery!” says Markham. “Of course, that’s not the safest way to handle things and it’s not easy to do. But it shows just how desperate employees can get when they need to make their work more mobile.”

Industrial mobile workstations can move around wherever they’re needed. They’re already common in hospitals and busy emergency rooms, and now industrial managers are also realizing how much time and money this mobile hardware can save.

Mobile workstations have become more sophisticated, especially when it comes to customization and power. They can be set up with laptops, tablets, printers, scanners, and other technology equipment to make the job at hand more efficient.

The main technical benefit of a mobile workstation is the built-in battery that’s specially designed for high energy demands and long hours of use.

“Batteries have just come such a long way,” says Markham. “The batteries in these workstations now have the ability to keep devices operating without interruption while you switch out individual batteries on other devices. It’s just so much more productive. If I need to process 20,000 cases, I can just load up a cart and get on with my work instead of wasting time going back and forth throughout the day to keep my devices going.”

Mobile workstations can even be configured to connect to Warehouse Management Software (WMS) to keep managers and supply chain partners constantly updated on progress.

“These solutions have really come of age,” says Markham. “And vendors can make an easy case for a fast return on investment.”

2. Intelligent Cabinets

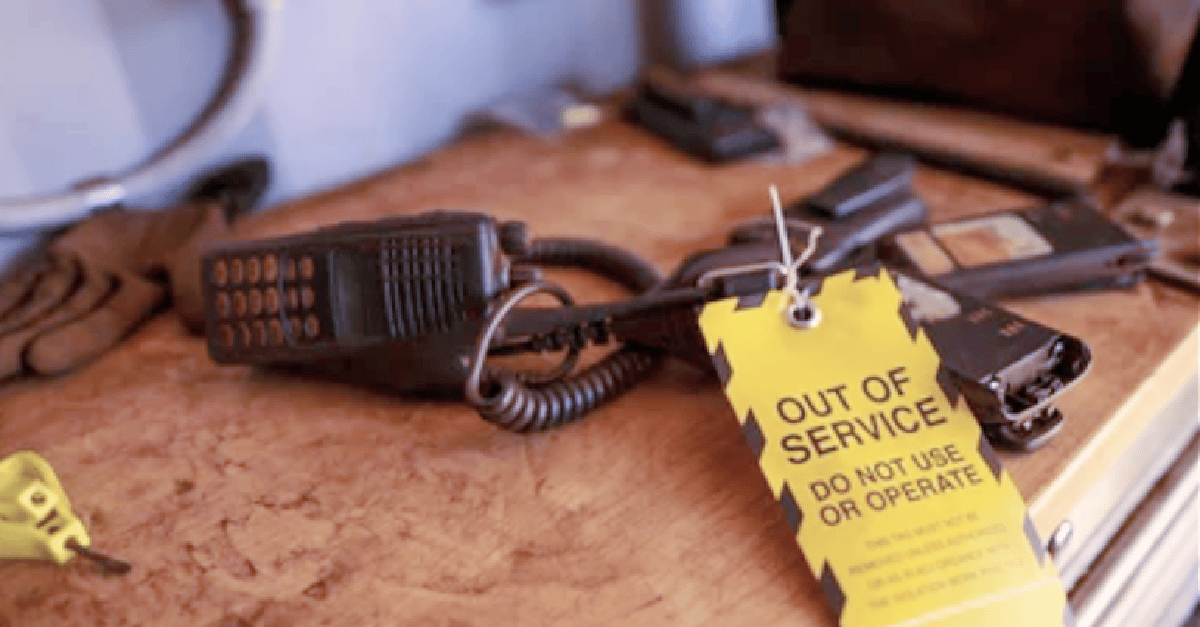

Look closely inside an operation that depends on handheld hardware tools, and you’ll likely find devices and batteries somewhere piled up on a table. Employees typically pick through the mess in search of “good” devices that help them work faster. If they’re lucky, the battery still holds a charge. Otherwise, the search continues for a battery that works. Markham says teams just learn to live with the chaos and managers have come to accept it as a part of operations.

“Let’s say you’ve got a hundred barcode scanners on the table, but only 80 or so make it back into charging stations at the end of the day. That’s the way things go, especially when you’ve got a lot of temporary workers because your workload has suddenly ballooned. Devices get lost or just walk away. There’s often no way to track their use or trace them to specific workers. At the end of the day, some devices never make it back to the table, and others don’t get fully pushed down into their chargers, so tomorrow, they won’t be ready to go.”

Markham says managers know they’re dealing with a mess of waste and inefficiency, and usually just deal with it by purchasing a bunch of extra devices and batteries.

“We get calls all the time requesting replacements. Everybody knows the right solution is better management of the hardware, not just buying more and more of it. Replacement costs can get ridiculous.”

Enter the world of intelligent cabinets. Imagine replacing your pile of devices and batteries with something resembling a high-tech vending machine capable of precisely issuing, tracking, and managing those devices.

“Maybe you swipe an identification card that unlocks the cabinet where you find a device charged and ready to go. You grab an extra battery too. It’s all documented, everything from the exact hardware you checked out to the time it happened. At the end of the day, you return everything and properly plug it back in for charging. The cabinet tracks it all and triggers alerts if something’s missing.”

Security is a big driver behind the purchase of intelligent cabinets. Automated tracking means fewer devices are lost or stolen, putting an end to the constant stream of replacement purchases. Valuable reporting functionality and analytics help too.

“The software inside these cabinets can make sure devices are charged properly and weak batteries are flagged. It also connects to the Internet so managers can monitor devices remotely, and can even deliver firmware updates overnight when not in use.”

Like mobile workstations, intelligent cabinets can be configured for your operation’s specific purposes. And equipment pick-up moves faster at the start of the workday when employees can just grab what they need and go, rather than waiting in line while devices and batteries are selected one by one.

“More businesses are waking up to the potential of these accessory solutions,” says Markham. “They’re realizing better management of their hardware means more productive employees and less time wasted, and that’s well worth checking into!”

Contact Commenco for more information about mobile workstations, intelligent cabinets, and smart hardware planning>>

See more wireless solutions for distribution and warehouse operations>>