Are your operations at a crossroads? If the way you work is evolving, expanding or changing directions, it may also be a good time to upgrade the labels you depend on.

“When warehouses, distribution centers, manufacturers and other industrial businesses make process or system changes, we’re often called in to help them choose the right labels,” says Craig Lynn, Commenco Business Development Manager and label specialist. “Label selection gets complicated quickly and our customers like having a local partner who can help them navigate the options.”

“Labels are often critical because they can seriously impact efficiency,” adds Mike Markham, Commenco’s Director of Technology Solutions. “They can play an important role in tightening up the movement of products and materials to save time and resources.”

A Complex Exploration.

When Lynn isn’t busy coordinating the label pipeline for regular Commenco customers or investigating changes in label technologies, he’s walking properties and talking to new customers about what they’re doing and what they need.

“Frequently the conversation begins with printers because that’s where everything starts,” says Lynn. “Different printers use different technologies that can impact the durability of labels. Less expensive options are only good for labels that don’t need to last much longer than the time it takes to ship a box to someone’s doorstep. But if you need labels to last longer or work harder than that, you may want a printer that’s more compatible with advanced label options.”

What will your labels stick to? Customers who are new to the game will usually just request ‘labels for boxes,’ which sounds simple enough, but it’s not. Lynn says you’d be surprised at the variety of box materials floating around. “Many of our customers are using low-end, clean, virgin corrugated boxes that just need labels with a standard permanent adhesive. But other customers come to us ready for something better because they tried basic options that didn’t work for their purposes. The labels fell off and created problems that were a hassle to fix.”

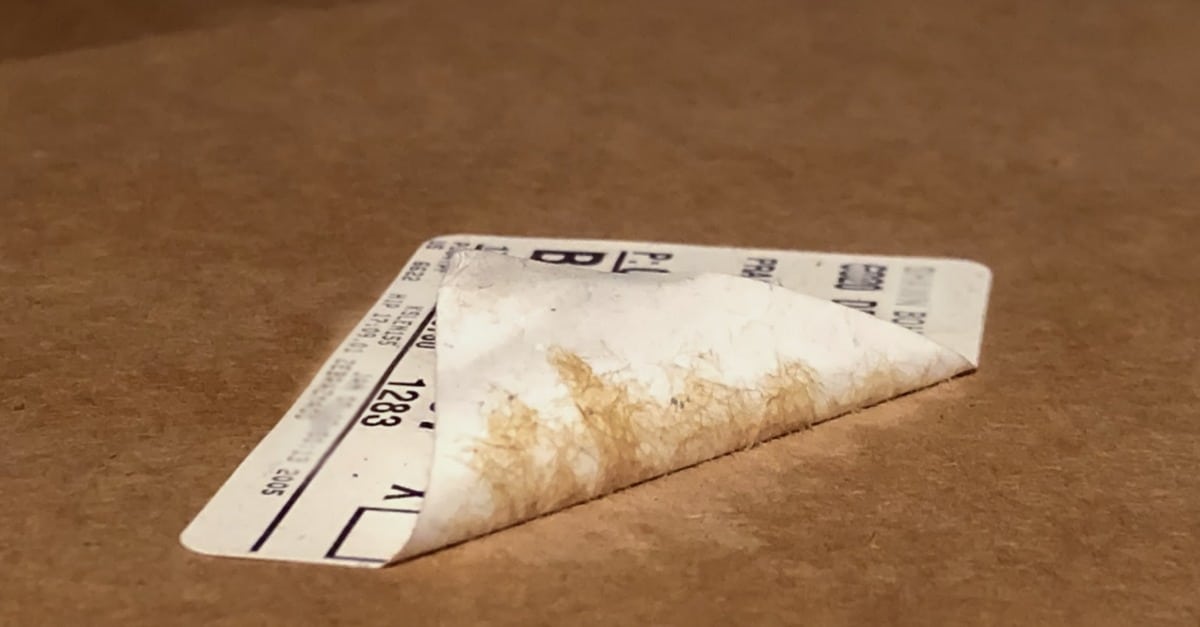

Advanced label options can be extremely advanced, involving a wide range of adhesives from those sticky enough to cling to difficult surfaces like silicon or rubber to those that can be removed and reapplied over and over again on a variety of surfaces. Lynn says surfaces can put other demands on adhesives too. “You’ve got flexible surfaces like bags and tricky surfaces like curved steel or glass vials used in healthcare environments to collect and store blood samples. The right adhesive can become extremely important.”

Environments where label printing takes place or where labels are attached can bring all kinds of additional complications. Not every label is printed at room temperature under typical conditions. Labels on materials stored outside like lumber, air conditioners, and automotive parts need to be made of materials that hold up under the stress of rain, snow, and ultraviolet sunlight. Chemical drums need chemical-resistant labels that last an extremely long time to ensure accurate identification and tracking. The list of special circumstances and applications goes on and on.

“Environmental temperature alone is a big factor,” says Markham. “The wrong labels will immediately fall off in a cold environment. And how they’re used matters too. Maybe you’re going to print a label and stick it on something that’s going into cold storage. That’s one thing. But what if you’re applying the label to a box that’s already frozen? Or maybe you need to remove and reapply the label over and over again in that environment. There are just so many scenarios.”

The lifecycle of a label often reveals all of the complicating factors that will need to go into smart label choices. Shipping labels are good examples of a short lifecycle spanning days or a few weeks, while on the other end of the spectrum, “Imagine a plastic bag that contains food that’s boiled and then stored in a freezer for a long time,” explains Lynn. “Not just any label will survive all of that. You’ll need special materials and protections in addition to the right adhesive.”

Powering Entire Industrial Operations.

Look closely around a warehouse or distribution center and you’ll notice labels everywhere, giving key direction to the movement of inventory. In addition to boxes and containers, you might see labels as large as street signs on walls, entrances, racks, and shelves, all working together to guide and enhance a fast-moving operation.

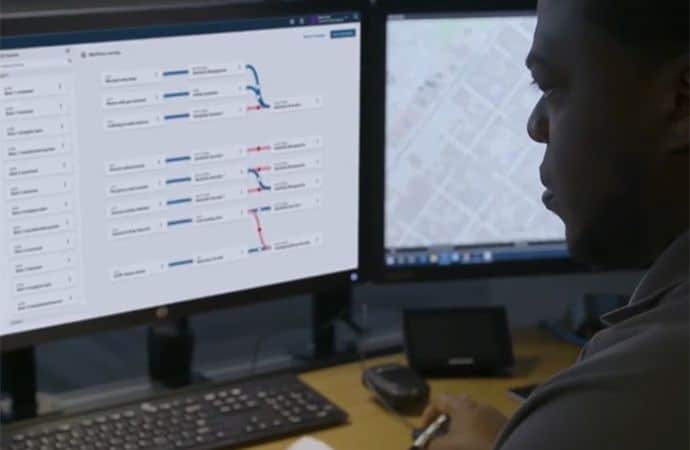

“Labels are a critical aspect of any Warehouse Management System (WMS) because scanning is by far the fastest and most efficient way to process data in a physical environment,” says Markham. “Labels immediately communicate all kinds of essential information to workers and also funnels it into WMS software that organizes the entire operation.”

“Think about a worker zipping through a warehouse moving materials on a forklift,” says Lynn. “He’s got a device that scans labels and he needs to use it while going 10 miles per hour. So, those labels need to be big enough, reflective enough, and positioned properly or his work is going to slow way down. Some labels may be 35 feet above the floor and he’s got to be able to scan those too.”

The size, selection, placement, and positioning of labels amounts to a science Lynn has been applying to industrial environments for decades. He’s learned to account for a mountain of variables ranging from the types of engines in hand-held scanners to scanning distances, RFID equipment, lighting, and even the size of each bar in a bar code. “It gets very complicated and we use prototype labels to test and work through scenarios inside each customer’s environment. It’s painstaking and there’s really no other way to do it.”

Actually, there is one other way to do it — the wrong way. Lynn has seen businesses rush through the process and then jump right in. “That’s the last thing you want to do. It’s a terrible feeling when you’ve worked dozens of hours and spent thousands of dollars to label your whole warehouse only to find you’ve done it wrong. Then you’ve got to spend even more time and money going back to fix everything. Testing up front before you start actually using the labels is the only way to go. And you might have to test again and again to get it right. Believe me. I know.”

At Commenco, we’ve learned that trust is the foundation of all our customer relationships and industrial label consulting is a prime example. Customers don’t always understand what we do but they know we do it right. When it comes to labels, it doesn’t take long for a customer to realize they need our expertise after their needs have expanded beyond traditional paper labels.

“Our customers figure out pretty quickly that we know more about this stuff than they do or even want to,” says Lynn. “They know we’ll cover everything from adhesives to placement and make sure they get going without interruption.”

“There’s a lot of risk involved and industrial operations just can’t take chances,” adds Markham. “It really pays to partner with someone who knows what you need and how to get it at the right price. That’s why a new label customer at Commenco almost always becomes a repeat customer.”

Are you ready for what’s next for your business?