Key Points:

- Inventory management software in the right hardware offers a competitive advantage

- Mobile workstations and intelligent cabinets are smart next steps

- Automated Mobile Robots are the future and leasing makes them affordable

Is your company’s competitive edge sharp enough? Here’s some food for thought for facility managers to clarity what technologies matter and how they could improve operations in 2022.

√ Need It Now

The digital age is now decades, not just years old, but we still occasionally walk into a warehouse or distribution center and see workers relying on clipboards, pencils, and spreadsheet printouts. Traditional tools and processes are becoming rare, but some operations continue to resist the switch to Warehouse Management Systems (WMS) and the hardware devices that feed them.

“If you’re still using clipboards and paper pick sheets, it’s just too much work and it’s happening too slowly,” says Mike Markham, Commenco’s Director of Technology Solutions. “Unfortunately there are businesses refusing to evolve and many can tell they’re getting left behind.”

You may feel like the same old ways of doing things have always worked well enough, but what you may not realize is your competition is zipping past you, working faster, getting more done, and doing it better. A WMS centralizes tracking and management of inventory in a way human brains, hands, and legs just can’t keep up with. For most warehouses, deployment of a WMS is standard. Markham says that’s because the systems are powerful, proven, and light years ahead of the last century’s methods.

“Businesses still relying on the old ways are used to them and just try to manage all the risks. You’ve got people writing things down wrong, other people reading them wrong and then loads of work documented on paper that gets damaged or destroyed by accident. It happens all the time. Competitive operations just can’t afford to put up with problems like that.”

A modern WMS also keeps your operation in close communication with the rest of the supply chain, synchronizing snapshots of productivity with manufacturers, retailers, and customers at both ends of the chain. And the right hardware connections make it all possible.

“A WMS is really only as good as the data that goes into it,” says Markham. “That’s where matching hardware ranging from wireless networking equipment to barcode scanners, printers, and the right labels becomes critical. It all works together as a productivity package that immediately makes you much more competitive.”

The ability to connect your WMS to shipping systems is a rising priority. Whether it’s an exclusive partnership with a particular shipping company or a third-party system that analyzes multiple shipping options, a WMS connection speeds up your overall operation even more and zeroes in on minimizing costs.

“Shipping calculations are getting more and more complex. They’re becoming more based on package dimensions than weight. The software will figure out your best options for each package so much better than your brain and a handheld calculator. There’s no question. If you’re still mainly shipping pallets, you may have a little more flexibility outside of a software solution, but those situations are becoming increasingly rare.”

+ Nice to Have

No matter how finely-tuned your warehouse or distribution center operation may be, there will always be work that comes along and doesn’t fit perfectly within the flow of standard processes. Special projects that draw workers and resources together for customized tasks are unavoidable. Batch mistakes are made that need to be corrected, supply chain partners pop up with special requests, or regulatory redirection requires sudden, custom adjustments. That’s where mobile workstations come in very handy and are nice to have.

“Mobile workstations allow you to move workers and their equipment to a specific location within the warehouse where a special project can be tackled,” says Markham. “It’s so much more efficient than shuttling around a bunch of inventory and materials.”

It’s the kind of thing that makes you wonder why you didn’t think of it before. Just imagine bundling up a computer, barcode scanner, and printer, or similar configuration, onto a single cart that can go anywhere a worker needs it to go for productivity right there on the spot. There’s no expensive integration or lengthy setup involved. And mobile workstations hitting the market these days include high-power batteries for uninterrupted productivity all day long.

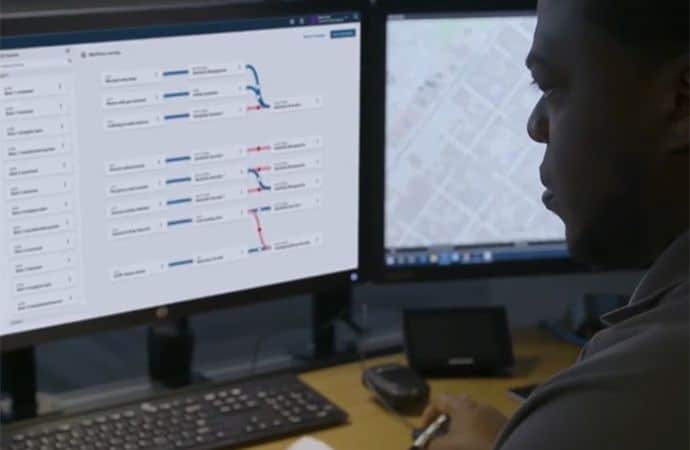

Are your workers wasting time sorting through piles to find devices and batteries that still work right? Efficiency-focused intelligent cabinets are nice to have too. They can make device and battery management a snap. Track who’s using equipment, how it’s used, and say goodbye to the expensive habit of just purchasing new hardware when items go missing.

“Intelligent cabinets are a security breakthrough,” says Markham. “They give you additional control over your tools so you don’t have to just keep buying more and more. Plus, these cabinets can even flag technical issues and support firmware updating. It’s a very big bang for the buck.”

> Start Thinking About

Are you ready for robotics? Don’t immediately dismiss the idea and just assume it’s beyond your needs and well beyond your budget. Automated Mobile Robots (AMR) may be just what you need and they’re now available in ways that work for even smaller businesses.

Markham says if you’re not already considering AMRs, you probably should be. “AMRs are quickly taking hold. They’re going to be a big part of the future of competitive warehouses and distribution centers. Now is the time to be thinking about how they might help you.”

But who can afford the purchase of high-tech robotic amenities, right? Here’s the good news. You no longer need the ambition or resources of Amazon to pump the power of AMRs into your operation. AMRs are rolling out through a service model. You don’t have to buy them. You just pay a regular fee that’s far more affordable, and the robots are delivered to your door, flashed with all the specifications and other particulars of your facility, and ready to work. There are no long learning curves, lunch breaks, or sick days.

“You’ll probably need some middleware that translates your WMS to data the AMRs need for control and direction, but that’s about it,” says Markham. “These robots are not for every operation, but if you’ve got people constantly running around gathering small products or materials, AMRs should be on your radar by now.”

Imagine a worker in an aisle of your warehouse full of thousands of different products. One by one, AMR carts line up for attention, ready with information about what they need. As the worker fills each cart, they roll off directly to the shipping area with orders ready to go. That’s just one scenario for AMR use, but it’s a common one with game-changing potential.

“You’re looking at a dramatic reduction in redundant movement across your warehouse. Things get done faster, more directly, and more accurately. Warehousing is so competitive anymore. You have to find new opportunities for speed and efficiency. AMRs are a big one.”

AMRs don’t replace standard tools like forklifts, barcode scanners, or wireless infrastructure. In fact, the robots work hand-in-hand with the rest of your hardware, bringing your whole system of productivity to new heights.

Maybe you only need the help of AMRs to handle volume peaks, like seasonal fluctuations in demand that ripple through your supply chain. Whether it’s full-time or just during peak times, AMRs as a service means you can ‘hire’ them only when you need them.

Go even farther and add in the flurry of specialized facility sensors hitting the market and you’ll be shaping a productivity powerhouse complete with high-tech monitoring of everything from equipment performance to environmental safety.

Work Smarter to Stay in the Game.

Few industries are as competitive as warehousing and distribution. Facilities are constantly running at capacity and technology can make room for more potential. If you’re serious about staying in a race that shows little mercy for the unprepared, keep your business equipped with modern essentials and always keep an eye on what’s coming next.