Key Points:

- Specialized software helps control costs, even for smaller manufacturers

- Tools designed to make workers more mobile are a smart move

- Technology that monitors signs of trouble could help protect your operation

The quest for smoother, smarter, and more productive manufacturing processes never ends and a robust collection of technology tools paves the way to the future. Here’s a snapshot of manufacturing plant technologies to spark inspiration for business in 2022.

√ Need It Now

You give a lot of attention to the output of your manufacturing processes, but could you be doing more on the front end? Better management of the flow of materials that feed your processes can mean lower costs and smarter use of resources. Smaller manufacturing businesses may not realize that ordering and stocking materials is better left to software than pencils and paper.

“It’s easy to order too much or too little if you’re doing the math in your head or on a clipboard,” says Mike Markham, Commenco’s Director of Technology Solutions. “Software will help you tighten up your overall operation. If you haven’t fully embraced it, now is the time.”

Warehouse Management Systems (WMS) and similar, specialized software are not exclusive to storage-focused businesses. Manufacturers can deploy the technology to help flatten the ups and downs in the stream of material supplies. Markham says even small manufacturers can reap big benefits from better control of what they need to produce what they sell.

“Whether you keep a supply of materials on-site or order as you go, a WMS can synchronize your stock of raw materials in a way that’s so much more efficient than relying only on general calculations and your own instincts.”

In the push to produce more and cut costs at the same time, manufacturers are examining their entire operation and deploying digital processes at every opportunity, not just in core production. Tighter coordination of material supplies and production needs is now a standard part of big picture thinking inside competitive facilities.

“True efficiency is having exactly what you need to get the job done and nothing more,” Markham emphasizes. “It’s knowing what you have and what you’re going to need at all times so you don’t come up short or overspend. A WMS or something similar is the only way.”

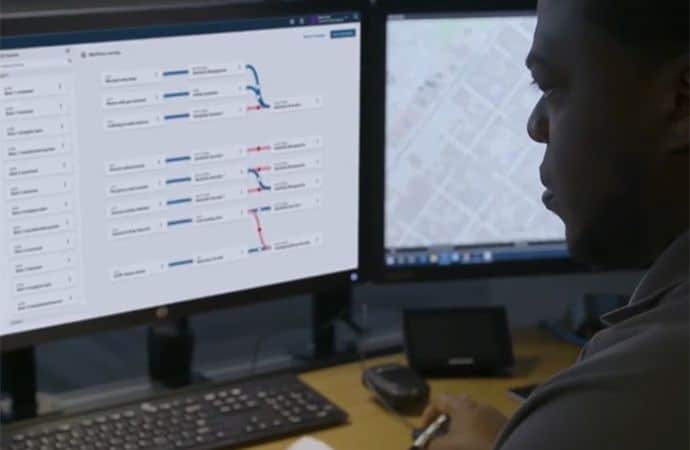

Deployment of a WMS also means deploying hardware tools that deliver a crystal clear picture of what your operation has to work with. Tools like barcode scanners that track the inflow of materials, rugged tablets that calculate data on the fly, and robust wireless networking infrastructure that connects all work and makes it immediate, turn a traditional manufacturing operation into a modern, lean machine.

“It all works together to make your business as efficient and as productive as possible,” says Markham. “And the return on investment speaks for itself.”

+ Nice to Have

Not everything goes as planned or turns out as expected inside a manufacturing facility, and that’s why modern mobile workstations are nice to have. While your central production processes hum along, special projects spin-off by design or by accident. Markham says equipping your people to tackle custom challenges efficiently keeps everything moving forward faster.

“Maybe there’s a label mistake on a batch of products or a recall that winds up as a big pile of product in the corner of your facility. Or maybe special samples need to be rushed to a customer or prospect. There are all kinds of reasons behind projects that require special attention and many businesses just deal with them as they come without thinking much about the impact in terms of time and labor.”

A mobile workstation easily moves employees and their tools to areas of your facility removed from your main production lines. The well-equipped, rolling carts focus special projects work and eliminate all the bouncing around workers usually do inside a facility to get the job done.

“Think how much easier it is to have a bundle ready to go that might include a computer, scanner, printer, and labels. An employee can quickly move it to an isolated area and get to work without a bunch of setup time and gathering the tools individually. There’s no integration required and plenty of power to keep devices going all day.”

Mobile workstations are designed as custom fits for a variety of purposes, and configurations can be adjusted for exactly what your specific team needs. The onboard batteries are up to the job too, lasting long hours to keep up with tight timelines. The batteries alone make mobile workstations hard to resist.

Larger manufacturers are now finding that intelligent cabinets are nice to have too. If you’re using a lot of handheld devices and cycling through piles of batteries, you’ll want to give these cabinets a closer look. They charge, track, and can even help with firmware and software updates.

> Start Thinking About

Electronic sensors are nothing new, but the explosion of hundreds of different kinds is just now starting to permeate the manufacturing industry. Major manufacturers are already diving deep into the world of sensors and smaller businesses shouldn’t hesitate.

“Sensors are really affordable depending on the job you want them to do,” says Markham. “They can range from a few dollars to thousands of dollars. Anyone who deploys them will tell you it’s money well spent.”

Sensors can save your operation with early detection when things begin to go wrong rather than finding out the hard way after substantial damage is done. The devices can ensure compliance with strict regulatory conditions too, and help optimize key technical points in your production processes. Markham says sensors can confirm your machinery is operating at peak performance and give you a heads up as parts begin to fail by flagging even tiny functional deviations from optimal ranges.

“Sensors can monitor the work of sensitive production equipment and even the employees managing it. The result is avoiding a huge spectrum of problems that were once just part of the price of doing business. The ability to jump on a solution early before a small issue has a chance to snowball and take down an entire production line is incredibly valuable for manufacturers.”

Sensing capabilities are valuable to all kinds of other businesses as well. From flood detection to damaging temperature fluctuations, sensors can raise awareness before disaster strikes.

“Just the potential to prevent catastrophe is going to make sensors standard inside many businesses,” says Markham. “They just make sense and they’re getting more sophisticated all the time.”

Work Smarter and Produce More.

Manufacturing has always pushed the limits of technology, but outside of the workhorse equipment that yields products, facility technologies can play a supporting role that impacts bottom lines. Keep a clear understanding of where your facility’s technology is at, and what’s coming on the horizon, and you’ll fine-tune an operation that’s always ready to meet the demands of the future.