Radio communications first sent us up a tower back in the 1950s when we began pioneering technical infrastructure in the Kansas City area. Radio was the primary ‘wireless’ service back then but today the wireless world is rapidly expanding and many of the new technologies require specialized support.

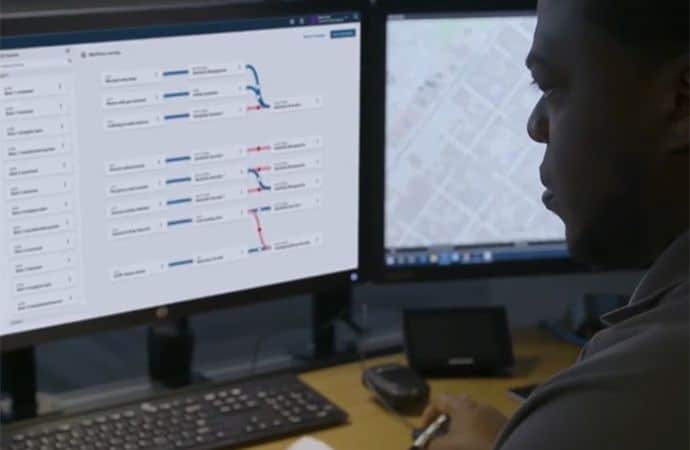

“We understand the physical realities of tower infrastructure,” says Ralph Aguilar, Commenco’s Director of Commercial Services. “We’ve built out our own infrastructure and created custom networks for many commercial and government buildings. Our experience puts us in a great position to support these new and evolving technologies.”

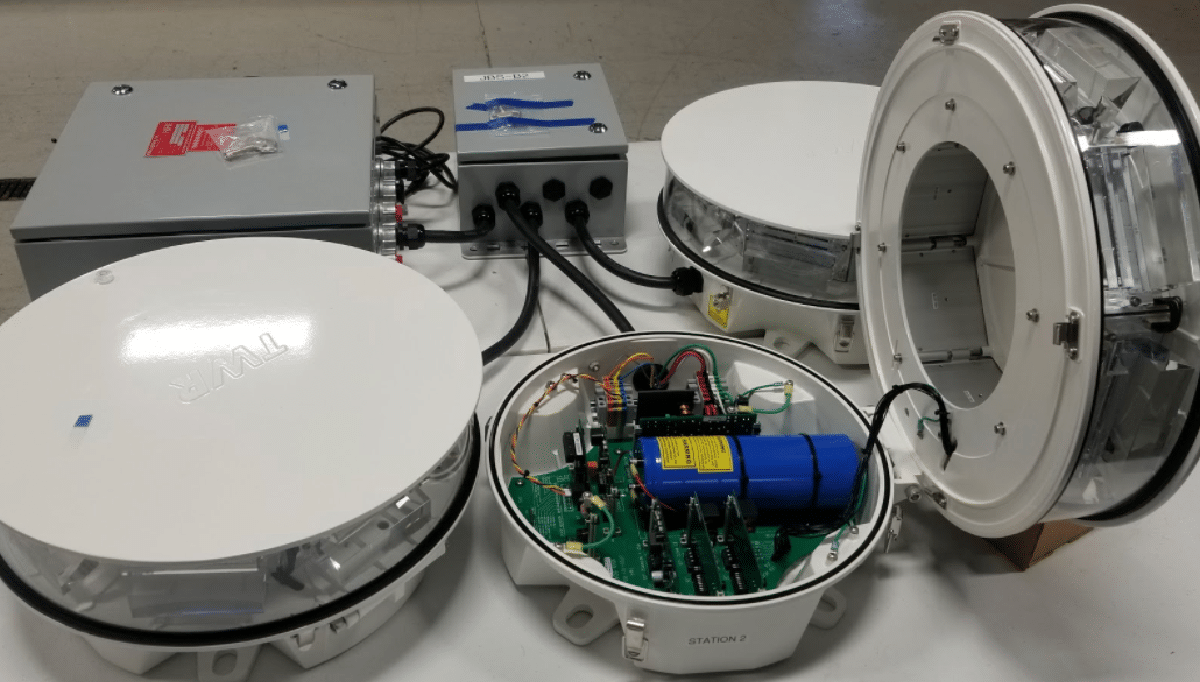

The 5G revolution is a big reason why demand for tower service has grown, but it’s not the only reason. Other trends, like infrastructure development in rural America have our crews busy linking guide towers so smaller communities can connect to the Internet. There’s also a lot of lighting work to be done as more tower owners see the value in replacing older incandescent bulbs with energy-efficient LEDs.

“Incandescents draw a lot of power,” says Aguilar. “So much power that we can hear the loud, oscillating hum of transformers when we pull up to service some of these towers.”

We’ve been out replacing incandescent bulbs on towers in the Kansas City area because more companies and municipalities are realizing the substantial cost and energy savings LEDs can bring.

There’s also a benefit to replacing old cables with new ones made to support LED lighting. They weigh considerably less and can significantly lighten the load on aging tower structures.

View From the Top

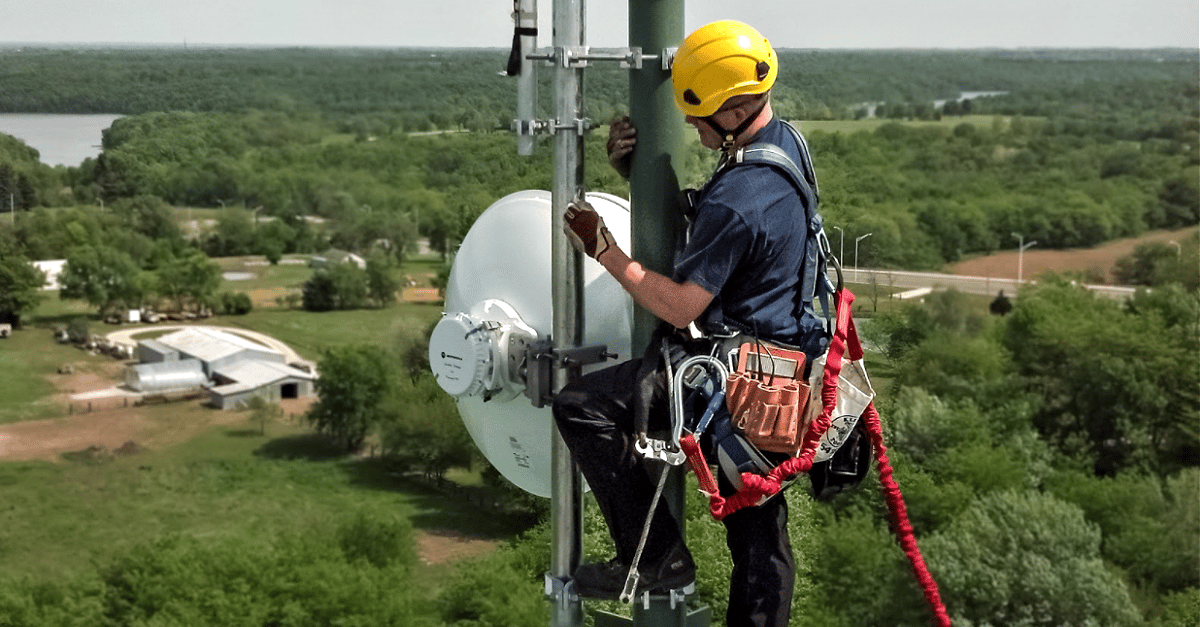

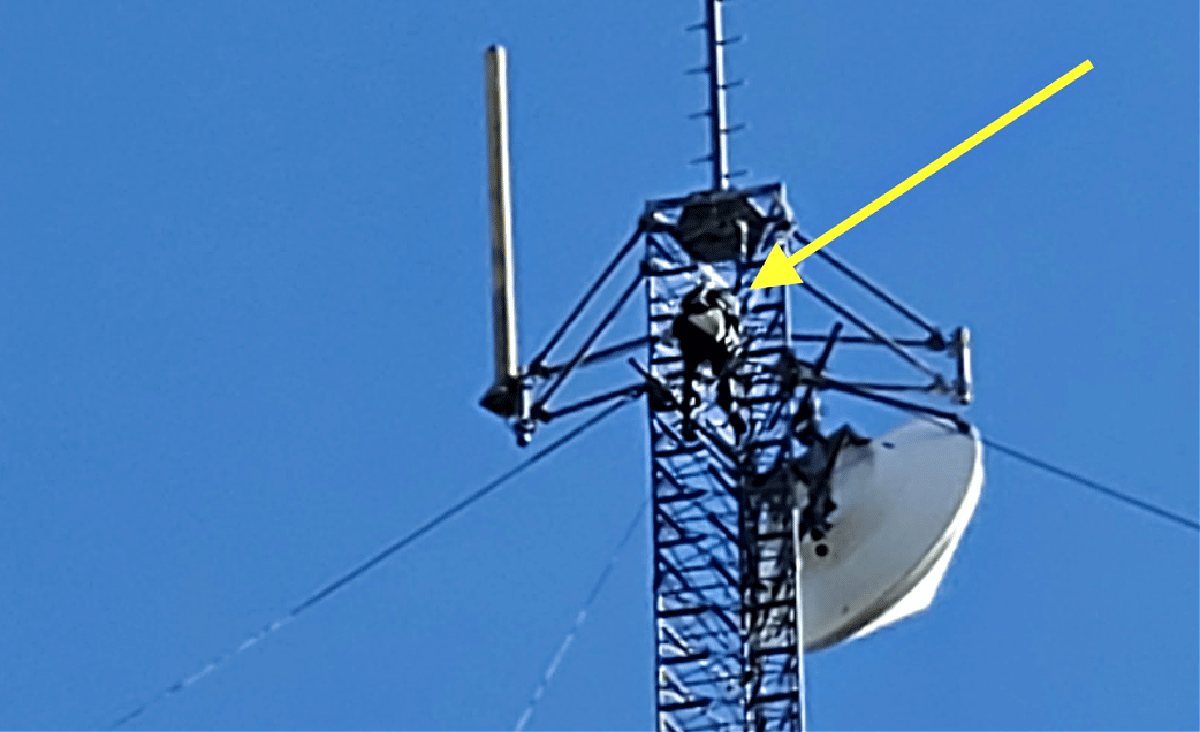

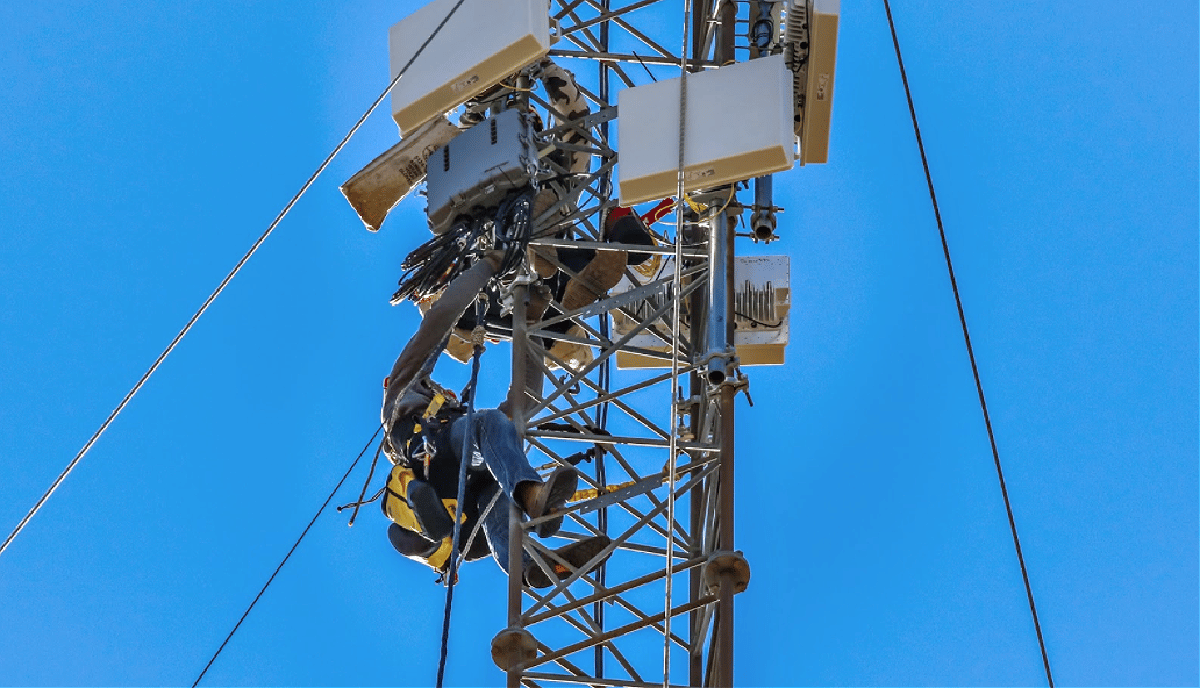

Tower service is fundamentally difficult work even before you come face-to-face with the specific technologies involved on any particular tower. The job is certainly not for the faint of heart. Commenco technicians currently climb as high as 500 feet, carrying equipment and pulling cables along with them in a slow, inch-by-inch journey to the top.

“They’re tied to the tower the entire time, connecting and disconnecting to secure each step as they go. It might take 45 minutes just to climb up and get into position before they can even begin the main work so they’ve got to be strong and mentally focused in order to stay safe.”

Our tower climbers brave the stress and dangerous conditions to inspect connections, install and replace parts, conduct testing, and make repairs on many of the region’s most active towers.

The higher they climb, the more dangerous the situation becomes, so safety is always priority number one. Commenco has an impeccable safety record that stretches back decades thanks to the good judgement of our technicians in the field. We take no chances in fog, rain, lightning, extreme heat or cold, or in any type of conditions that have the potential to put someone’s life at risk.

“We protect our people at all costs,” says Aguilar. “We never ask our technicians to take unnecessary risks or do anything that makes them feel unsafe. Their work is difficult and exhausting so we encourage plenty of rest between jobs and never pressure them to hurry while working. We’re very conservative in our expectations. Anything more is just not worth it.”

All Commenco technicians receive advanced safety training and are certified by OSHA so nothing is left to chance.

“We have some great opportunities to join Team Commenco and are willing to train the right candidates,” says Aguilar. “We don’t expect applicants to bring 40+ years of experience as our current Tower Manager has, but we do expect anyone serious about the opportunity to share our commitment to safety and service excellence.”

Aguilar says technicians may be offered additional specialized training and more opportunities for growth, depending on the range of technologies and services the company embraces.

“We want to focus on technologies and services that will help our customers the most,” says Aguilar. “We can always adjust and expand our services if we discover better solutions along the way.”