Tower owners, utility companies, and public entities around the region are in the process of switching out hundreds of old incandescent lights for more efficient LEDs. It’s a big job. Here’s why it matters.

The Old System Is Burning Out.

LED is taking over everything from house and car lights to streetlights, security lights and now tower lights. The long era marked by constantly changing out hot burning tower incandescents and paying high energy bills tied to high voltage, is dimming. Only a few towers in the Kansas City area have fully switched to new LED systems, but nearly all of them are in the strike zone.

“The LED rush is on. There’s really nothing to lose and a lot to gain,” says Larry Morris, Commenco’s Senior Field Technician and LED specialist. “For example, Johnson County, Kansas switched one of its towers to LED and quickly saved enough money in energy costs to pay for switching two more towers. That pretty much says it all.”

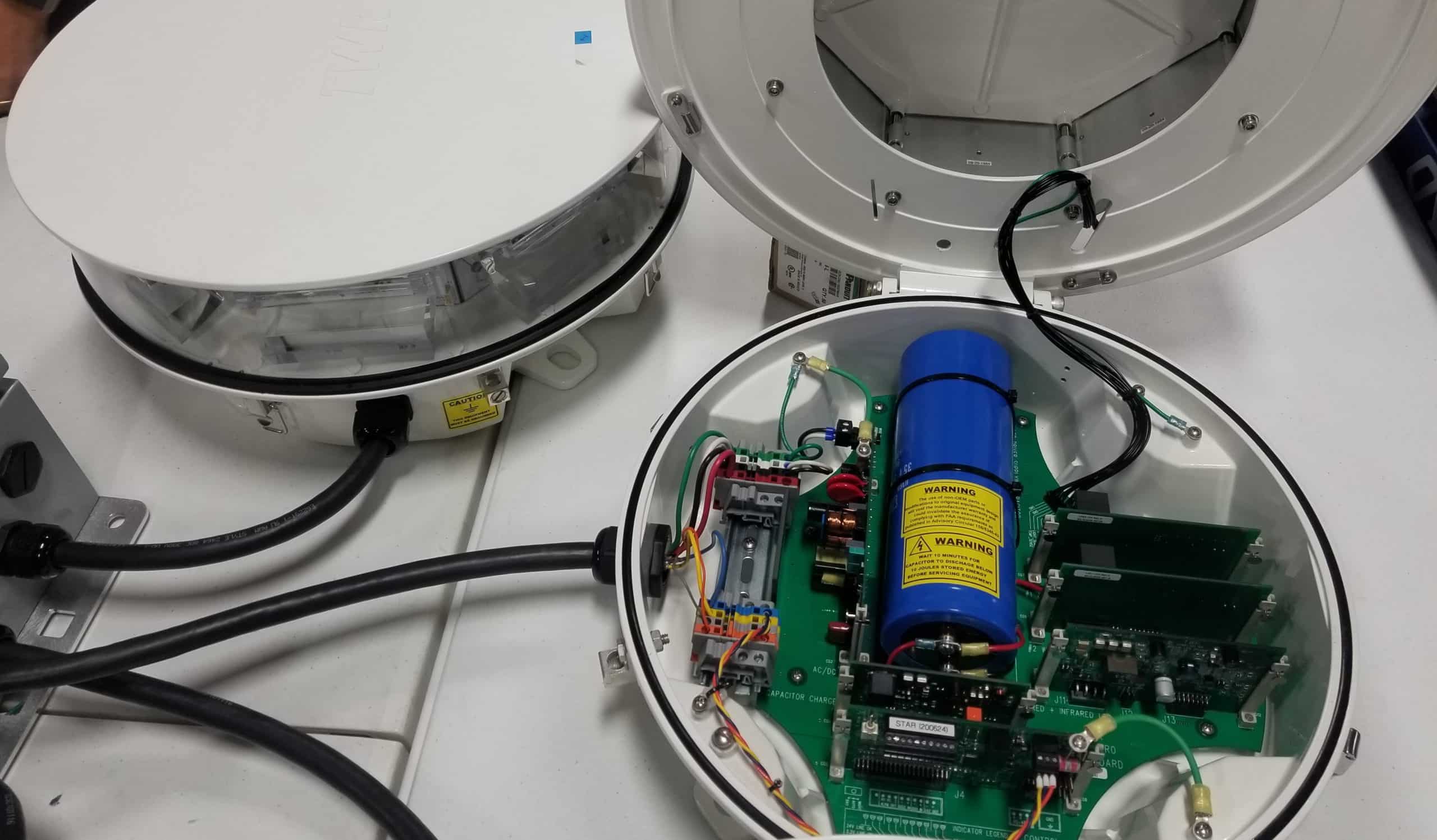

As old flash tube technology disappears from inside red and white tower lights, LED is lighting up excitement around a better way of doing things — finally. LED lights were too dim for years, but now they perform as well as the old bulbs they’re replacing while only needing a fraction of the energy. LEDs generate far less heat, require fewer, lighter cables, and are available in options that are up to the heavy-duty job on towers.

“The upfront investment isn’t such a big deal anymore,” says Morris. “Energy savings offset it and you also say goodbye to expensive incandescent bulb replacements. Changing a burnt flash tube high up a tower can cost thousands of dollars. And then the next day, another one could go out.”

Morris is a pioneer in the LED revolution in the context of local towers. He’s been studying the rise of LED for years and put his knowledge to work recently when the maintenance of a tower in Cass County, Missouri started weighing on minds and budgets. Morris researched options, selected the right LED system for the job, and then installed and deployed it as a complete replacement for its incandescent predecessor.

Of everything he learned along the way, one lesson rises to the top. “You really need a specialized tower team with broad knowledge to do the work right.”

Good Tower Teams Know LED Systems Inside and Out.

While both incandescents and LEDs are tied to the same electrical systems, they speak different languages. It can get really confusing if you don’t have a tower team to translate technical standards and rigid FAA requirements.

“The FAA has requirements that ensure pilots can easily see the lights on towers,” says Morris. “An LED system can allow you to meet those requirements in a smarter way by doing things like taking advantage of finer control over flash patterns. But you have to understand the requirements and what different LED systems can do in order to make it happen.”

Understanding how to choose an LED system and match it to a specific tower is the key to reaping the efficiency and money-saving benefits without sacrificing brightness standards. Even the cabling needs to be carefully arranged to make the most of the system or you can wind up burning energy needlessly. Beacons must be properly connected and flash patterns must be tuned to perfection.

Understanding the Entire Tower Ecosystem.

There’s a lot more involved at local towers than light bulbs and cables. Powerful transformers continuously pump electricity up the towers. You’ll also find backup generators, air conditioners, alarms, radio system components, industrial dehydrators to guard against moisture, and microwave infrastructure linking communications across multiple towers. Morris encourages tower owners and commercial contractors to make a tower team a priority when it comes to the lighting system.

“Electrical contractors will do everything necessary to set up power leading to the tower, but that’s where their work will typically stop. The tower team should take it from there. They don’t need to be experts in things like hydration and air conditioning, but they should have an understanding of how everything inside the tower works and how it’s interrelated.”

Understanding the tower ecosystem delivers higher assurance that everything is set up properly and working correctly when you switch to LED. It also saves troubleshooting and repair time later when a tower team flags emerging issues and reaches out to respective contractors before there’s a crisis.

“We’ve really got a head start at Commenco because of all the radio work we’ve done since the 1950s,” explains Morris. “We designed, installed and deployed the radio systems in most of these towers and also connected the towers to form communications networks. So, we’re already very familiar with everything ranging from the purpose of the towers to the equipment inside and how it all works together.”

They Must Be Expert Climbers.

Understanding new LED technologies and how they fit into tower ecosystems is essential, but the right tower team for your LED transition must also know how to climb. Scaling towers is extremely challenging mental and physical work. You need a tower team experienced in the slow, methodical process of safely moving up, down and around towers to take down incandescent components and install LEDs.

“It’s a pretty rare skill and it’s critical,” emphasizes Morris. “Trusting trained professionals with the right certifications means not having to lose sleep worrying about safety. It also gives you confidence that the work is being done exactly right.”

Trained climbers use specialized equipment for moving around structures hundreds of feet tall and know how to carry equipment up and down without putting themselves or the technology at risk. Morris says they know when the weather is right for climbing and when it’s wrong, and keep a sharp eye on the limits of what they can do in varying conditions.

“Even larger electrical contractors may not have these kinds of skilled workers. And you can’t easily find people who are willing to do the job. They’ve got to have an advanced understanding about how all of these systems work in addition to climbing.”

Commenco made its mark with tower expertise long ago and we’re excited about the new application of our knowledge in the LED revolution. Our understanding of LED and related tower systems in addition to our climbing expertise makes us a unique option for bringing local towers into modern times.